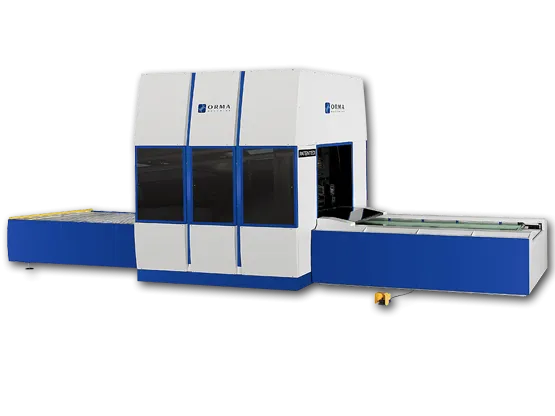

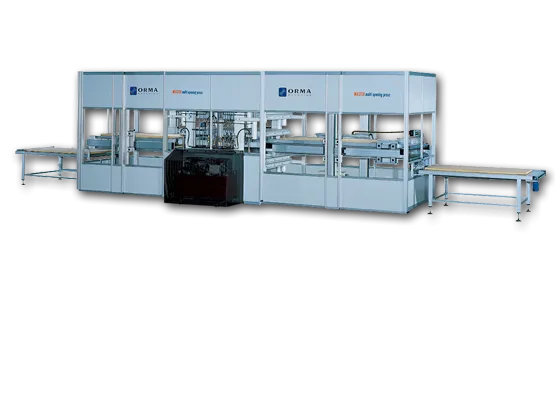

The ORMAMACCHINE MASTERpress has been thought as a high capacity pressing plant both into the flush doors and panel covering with veneer, decorative paper, plastic laminate fields. The machine is composed by superposed number of platens creating, according to the customer requirements, a number of working daylights independently get in pressure. By means of a PATENTED NEW AND REVOLUTIONARY system, each working daylight can be blocked once under pressure. This method allows the sequential opening/uloading and loading/closing operations of each single opening without considering the condition of the others that may remain closed under pressure. According to what above, it is possible to exploit the laying up time, turning it into an active time to enormously cut the “dead time” to allow a 1000 panel production/8 hour shift (machine with 8 daylights). The standard pressing plant that may be integrated by all our automation devices is composed by: powered loading belt with horizontal movement allowing its going inside the press, the multi-daylight press that by means of a suitable hydraulic controls, drives the different working daylights to the powered loading belt height, and powered roller unloading device. The working parameters are set through the graphic keyboard on which during all the different working steps, the machine conditions are constantly displayed such as: – Panel dimension – Specific pressure to be applied – Number of daylights to be used – Thickness of the panels to be processed The machine automatically carries either the panel positioning inside the working daylights and the specific pressure to be applied on the panel calculation MASTER is the only machine that gives the possibility to different working parameters setting for any single working daylight. WORKING CYCLE START When the working cycle staits, the machine carries out its setting: all working daylights are set in pressure and the pressing unit positioned at the height of the first opening to be loaded. The mobile structure vertical movement is controlled by a rack and pinion system along with a special compensating device granting, in this way, a perfect parallel movement. Electronic systems working on the four sides of the platens manage independently the lifting cylinders for a perfect alignment of the platen to the loading unit. Meanwhile the lifting operation is carried out, the opening of the movable upper platen is done. The upper movable platen with the underlying one crates the first working daylight, kept in pressure as all the others working daylights (actually empty) by means of a spe cial devices that are the hearth of the ORMAMACCHINE PATENTED SYSTEM.

The panel to be processed, laid up on an additional working station, is placed over the loading belt that moves inside the press once the panel has reached a referring position. During the return step, the loading belt rotates contrary wise to the transfer movement at the same linear speed leaving the panel inside the press daylight. The daylight is closed and get in pressure by closing the movable platen and the underlying one that is blocked and make it integral, in the meantime the structure moves vertically in order to align the second working daylight to the loading belt. The movable platen opens along with the underlying one and the second working daylight opens. The loading, the closing and the getting in pressure are the same as the above described for the first working daylight. When the working daylights loading sequence, for the all is over, the structure moves vertically and comes back to the first daylight where the first loaded panel is laying for the whole working cycle. Now the glue has dried up and the panel is ready to be unloaded. With the new loading cycle, the loader, during its transfer inside the press, unloads the processed panel by pushing and moving it over the unloading roller device that starts moving as soon as the panel is detected.